BASALT FIBER COMPOSITE

BASALT FIBER COMPOSITE

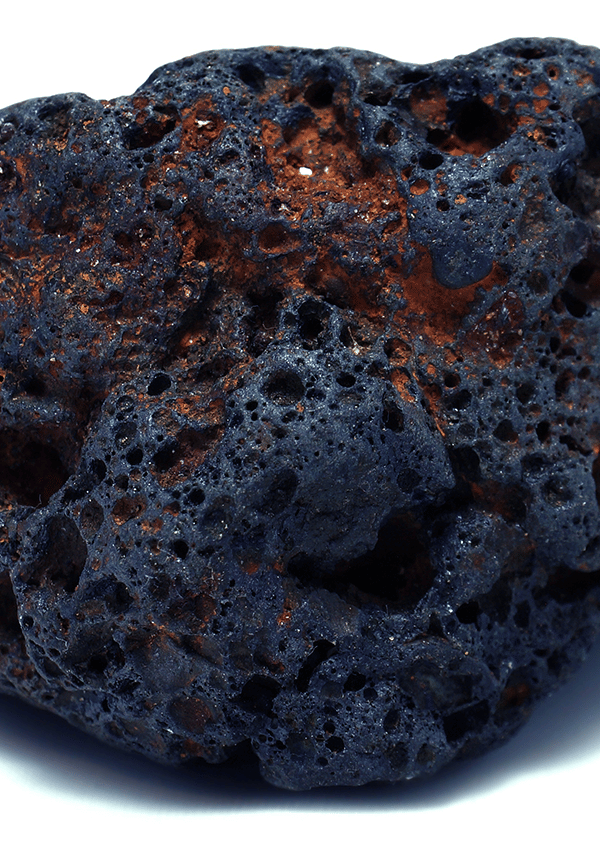

Basalt fiber is produced from a Basalt rock, which is a product of volcanic activity and can be found in a huge amount on the Earth, these composites are superior as they possess excellent properties such as sound insulation, heat and vibration and stability, high resistance to high temperature and possesses durability and strength.

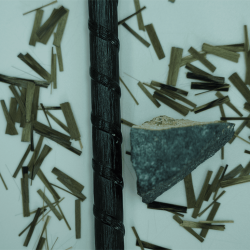

Basalt fibers composite is a new type of material, which is made by blending basalt fiber with plastic. It has excellent physical and mechanical properties, such as high strength, good ductility, low density and so on. The applications of basalt fibers composite include but not limited to flooring and wall covering, industrial materials, shipbuilding, semi-conductor industry, etc.

Basalt fibers and their composites are a superior material in high temperature and tough environments, play an important role in composite materials. The following are some of the key properties of basalt fibers composite:

Basalt fibers and their composites shows greater resistance to salt and water solutions as compared to other fibers composites. This is because of the nano-phase particles that are present in the basalt fibers.

Basalt fibers and their composites s have wider temperature range -200 to about 650/800°C, this is largely due to the mineral composition of it and the presence of many micropores within it, which makes basalt fibers and their composites very effective in fire protection and thermal insulation in buildings.

Basalt fibers and their composites is characterized by high tensile strength, high fatigue resistance and good impact toughness compared with other fibers composites.

Basalt fiber composite can be used in multiple fields, including :

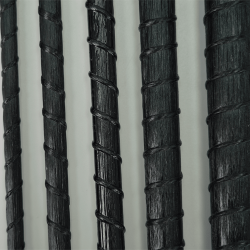

Basalt fiber composite applications in building and construction is rapidly growing, for examples, civil structures, bridges, tunnels, railways sleepers and road construction, this is attributed for several advantages which basalt fiber can offer it, such as high strength, low density, and good chemical stability.

Basalt fiber Composite is used in Pipes and gas cylinders industry to decrease the weight of the material and thus it is suited for pipeline transportation of crude oil, natural gas, and other fluids.

Basalt fiber Composite are stronger than steel, lighter than glass fiber rebar and conduct heat better than copper. In the energy production sector, basalt fiber can be used to make wind turbine blades, solar panels, and even power grid infrastructure.

Arab Basalt Fiber Company envisions a world where all future construction and repairs are harmless to the planet, our health, and our resources. Join our mission for a better future.

Comments

Post a Comment